VietSonic – Ultrasonic Sewing Machines – A Modern Solution for Industrial Manufacturing

1. Challenges in the Modern Sewing Industry

In today’s fast-paced manufacturing environment, businesses are under increasing pressure to deliver high productivity, consistent quality, and cost efficiency. Traditional sewing methods often reveal limitations such as thread breakage, inconsistent stitching, and fabric fraying, especially in high-demand applications like medical masks, filter bags, and protective suits.

This is where ultrasonic sewing machines emerge as an ideal alternative.

2. Ultrasonic Technology – A Superior Alternative

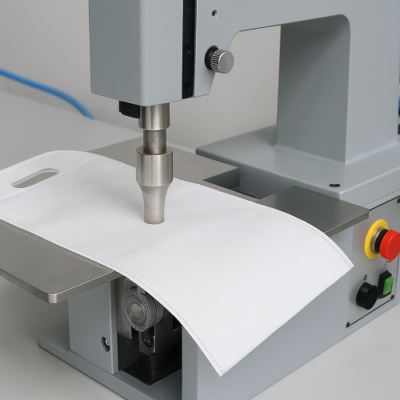

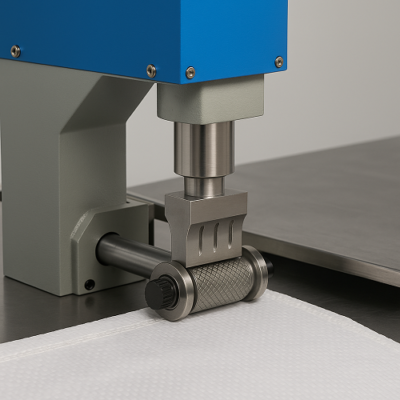

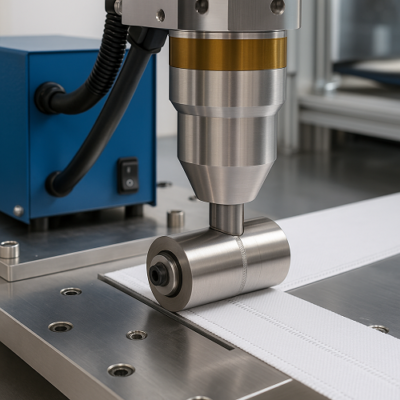

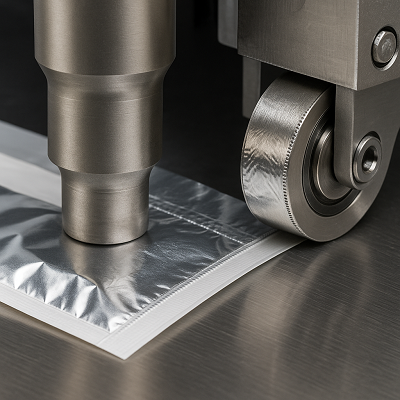

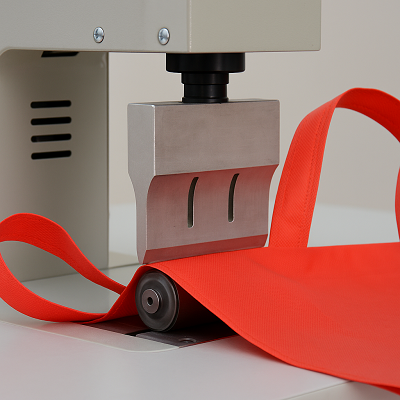

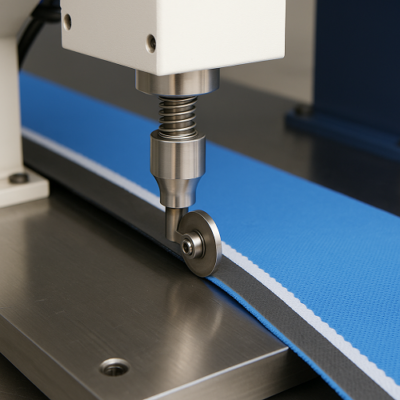

Unlike conventional sewing machines, ultrasonic sewing machines do not use needles or thread. Instead, they apply high-frequency ultrasonic vibrations to generate localized heat through friction, melting and bonding fabric layers together seamlessly.

Common applications include:

- Sealing non-woven fabrics

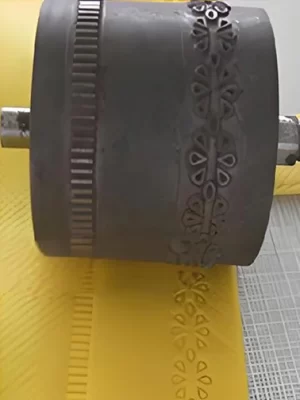

- Creating decorative or structural patterns

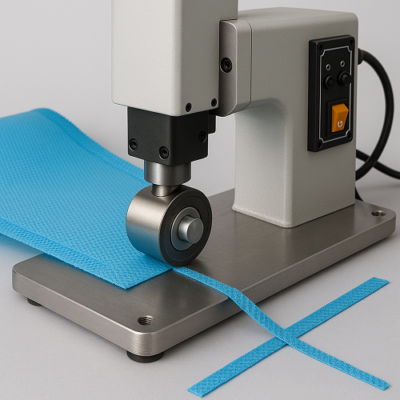

- Simultaneous cutting and sealing without leaving frayed edges

3. Benefits of Using Ultrasonic Sewing Machines

By adopting needle-free ultrasonic welding machines, businesses enjoy a wide range of advantages:

- High production speed – ideal for automated production lines.

- Clean operation – no loose threads or lint, ensuring hygienic results for medical or food-grade products.

- Strong and waterproof seams

- Lower operating costs – no thread consumption, minimal maintenance, and fewer mechanical breakdowns.

Many ultrasonic systems also function as cut-and-seal machines, combining multiple steps into a single pass.

4. VietSonic – A Complete Local Solution in Vietnam

VietSonic is proud to be one of the few companies in Vietnam capable of designing, manufacturing, consulting, installing, and operating ultrasonic sewing machines tailored to specific needs.

Why choose ultrasonic machines from VietSonic?

- Custom design: Adapted to various materials, patterns, sizes, and power needs.

- Locally manufactured: Competitive pricing and short lead times.

- On-site consulting & installation: Experienced engineers who understand local production requirements.

- Outstanding warranty: Fast repair service, available spare parts, and regular maintenance support.

VietSonic doesn’t just supply machines — we partner with clients from concept to stable operation.

Ultrasonic sewing machines are proving essential in industries requiring precision, cleanliness, and speed. With in-house engineering and strong technical support, VietSonic is ready to be your trusted partner in the journey toward automation and production optimization.

Contact VietSonic today for a free consultation or to arrange a live machine demo at your facility!