VietSonic — a pioneer in ultrasonic technology applications in Vietnam — presents a concise, easy-to-understand overview of ultrasonic welding so that factory owners and production managers can immediately visualize the value this technology brings.

1. What is Ultrasonic Welding? (Concise & Clear)

Ultrasonic Welding is a method of joining two parts using high-frequency vibrations (typically 20–40 kHz). Instead of heating the entire component or using adhesives, the welding horn transmits vibrational waves to the contact area — creating micro-friction and localized heat, causing the interface to melt and fuse into a solid bond very quickly (often under 1 second for many applications).

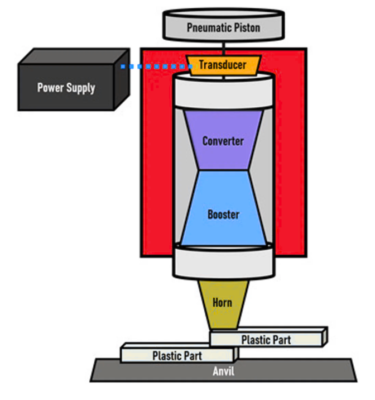

2. Ultrasonic Welding Machine Components (Illustrated)

To visualize easily, you can view the ultrasonic welding machine as an “energy transmission chain” — starting from electricity, converting into mechanical vibration, and finally transmitting into the material to be welded.

A standard ultrasonic welding system consists of the following main components:

Power Supply (Generator): Generates high-frequency electrical current, typically ranging from 20 kHz – 40 kHz.

Transducer (Converter): Converts high-frequency electrical current into mechanical vibrations.

Booster: Amplifies the vibrations, helping energy transmit more powerfully and uniformly.

Horn (Sonotrode): The part that directly contacts the plastic component, delivering ultrasonic energy to the weld joint.

Anvil (Fixture/Nest): Holds the plastic parts firmly in place during the welding process, ensuring precision.

Pneumatic Piston: Applies and regulates the pressure between the two surfaces during welding.

When the system operates, ultrasonic energy is transmitted from the generator → horn → plastic material, causing molecules at the contact interface to vibrate rapidly and generate localized heat, creating a strong bond without the need for glue, screws, or external heat.

3. Working Principle — Explained in 3 Simple Steps

Vibration Generation: The Generator outputs a high-frequency signal; the converter transforms it into mechanical vibration.

Transmission & Localized Friction: The Horn transmits vibrations to the contact area, creating internal friction that causes localized melting of the surface.

Compression & Solidification: When the waves stop, pressure is maintained for a split second to allow the weld to cool and stabilize — completing a solid bond.

4. Why Should Businesses Care? (Practical Benefits)

Fast: Welds can be completed in <1 second for many components.

No Glue or Screws Needed: Reduces consumable costs and product contamination.

No Heating of the Entire Product: Minimizes deformation, suitable for thin materials or heat-sensitive components.

Aesthetic & Uniform Welds: Ideal for products requiring high aesthetics (labels, tags, device casings).

Safe & Clean: Smoke-free, minimal chemical by-products.

5. Real-World Applications (High Demand Sectors)

Textile & Garment: Welding labels, tags, non-woven fabric edges.

Medical: Manufacturing masks, medical bags, filter membrane bonding.

Electronics: Fixing plastic components, device casings.

Automotive: Spot welding of plastic parts, interior accessories.

Packaging: Sealing bags, thin films.

Ultrasonic welding is a fast, clean, and cost-effective solution for many manufacturing applications. By optimizing frequency, amplitude, force, and weld time, businesses can achieve strong, aesthetic bonds without glue or excessive heat. VietSonic is ready to accompany you from sample testing to factory deployment.

📩 Want to test the machine on your samples?

📞 Contact: 0938 49 3366 (Mr. Hai)