Ultrasonic Non-Woven Bag Sewing Machine – Modern Production Solution from VietSonic

In the context of growing environmental awareness, non-woven bags are gradually replacing traditional nylon bags. To meet the demand for efficient production of these bags, the ultrasonic sewing machine supplied by VietSonic is the optimal solution featuring modern technology, needle-free operation, and high durability.

What is an Ultrasonic Non-Woven Bag Sewing Machine?

An ultrasonic non-woven bag sewing machine is specialized equipment that uses ultrasonic waves to weld fabric edges instead of using needles and thread like conventional sewing machines. This technology creates strong, aesthetically pleasing seams without leaving needle holes, making it highly suitable for non-woven fabrics such as PP spunbond.

Outstanding Advantages of VietSonic Ultrasonic Sewing Machine

- Needle & Thread Free: Minimizes material damage and saves operating costs.

- Strong – Highly Aesthetic Seams: Seamless welding, no needle punctures, no unraveling threads.

- High Productivity: Fast sewing speed, suitable for mass production.

- Simple Operation: User-friendly design, easy to control and maintain.

- Eco-Friendly: Reduces industrial waste and generates no harmful heat.

Applications of Ultrasonic Sewing Machine in Bag Production

VietSonic ultrasonic sewing machines are used to produce various types of non-woven bags, especially:

- Supermarket bags

- Drawstring bags

- Gift bags

- Advertising bags – with corporate logo printing

- Eco-friendly packaging

In particular, the non-woven drawstring bag line is popular due to its convenience, compactness, and reusability.

Non-Woven Bag Production Process with Ultrasonic Machine

- Cut non-woven fabric to required bag dimensions.

- Print logo or custom content (if any).

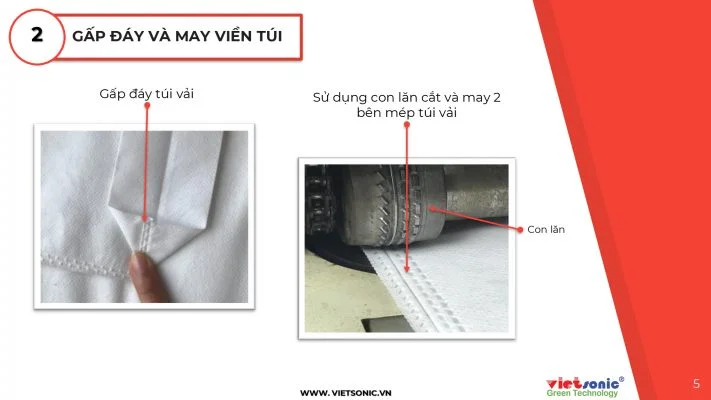

- Sew/join bag edges using the ultrasonic sewing machine.

- Create bag mouth and leave a channel for drawstring (for drawstring bags).

- Thread the drawstring and finish the bag.

This entire process can be automated or semi-automated depending on the production model, ensuring high efficiency and uniformity.

Technical Configuration of VietSonic Ultrasonic Sewing Machine

- Power: 1,200 – 2,000W

- Ultrasonic Frequency: 20kHz

- Sewing Speed: Up to 15 – 30 meters/minute

- Sealing Width: 10 – 15 mm (depending on design)

- Compatible Materials: PP non-woven, PE fabric, PET, thin nylon

- Power Supply: 220V – 50Hz

- Machine Dimensions: Flexible design based on customer needs

- Options: Sawtooth pattern welding head, round wave, or special patterns upon request

VietSonic – Trusted Partner in Ultrasonic Technology

With over 15 years of experience supplying high-quality ultrasonic machinery in Vietnam, VietSonic is committed to:

- Consulting optimal solutions for each production scale.

- Providing genuine machines with long-term warranties.

- Rapid and professional technical support.

- On-site operation training.

If you are looking for an effective non-woven bag production solution, do not hesitate to contact VietSonic for the best advice and quotation!

📞 Contact Information

VIETNAM ULTRASONIC EQUIPMENT COMPANY LIMITED (VietSonic)

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn