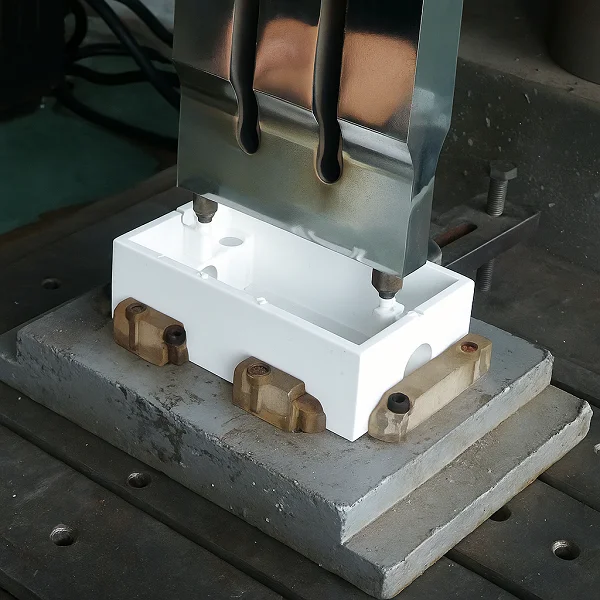

Ultrasonic Welding Machine and Application of Inserting Metal Threaded Inserts into ABS Plastic Boxes – Optimal Solution from VietSonic

In modern manufacturing, connecting plastic and metal is always a challenge. Ultrasonic welding technology has created a breakthrough, especially when inserting metal threaded inserts into plastic products, typically ABS plastic boxes. This article will delve into this technology, how it is applied effectively, illustrated through VietSonic products.

What Is Ultrasonic Welding?

Ultrasonic welding uses high-frequency waves. These waves create frictional heat at the material contact point, melting and bonding the materials. To insert metal threads into plastic, the waves locally melt the plastic. The thread is inserted and fixed firmly when the plastic cools. This process is very fast and clean, creating a sustainable bond without glue or screws.