VietSonic Ultrasonic Sewing Machine: Industrial Standard Fabric Cutting Solution

Overview Introduction

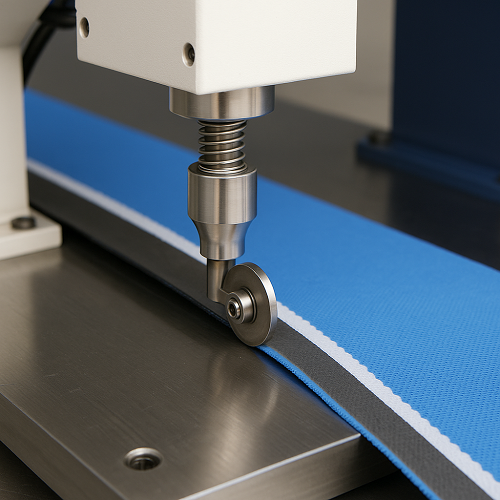

The ultrasonic sewing machine is a device that does not use needles and thread but utilizes high-frequency ultrasonic waves to create friction, heat, and bond layers of synthetic or non-woven fabrics. With an integrated cutting roller, VietSonic provides a solution to cut and seal in a single step, completely eliminating fraying – enhancing quality and production efficiency.