Ultrasonic Sewing Machine – Modern Textile Welding Technology from VietSonic

1. Overview and Role

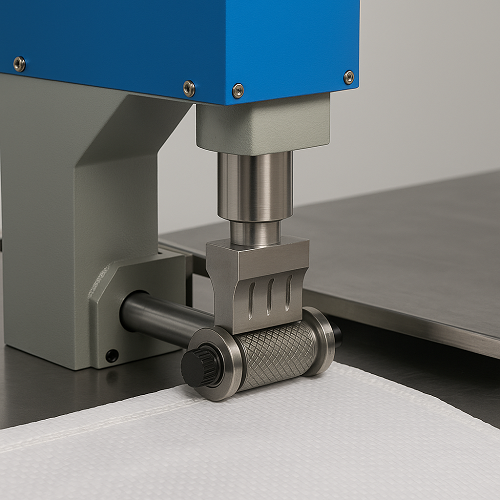

The VietSonic ultrasonic sewing machine operates at high frequency (20 kHz) with powerful output (1,500–2,000 W) and roller speeds of 0–20 m/min. It is a breakthrough compared to traditional sewing machines:

- Needle-free & thread-free: Operates using ultrasonic waves to generate localized heat for bonding PP films, non-woven fabrics, and laminated films.

- Seamless welds: Lint-free and highly aesthetic.