VietSonic Ultrasonic Sewing Machine – Optimizing Production…

1. Introduction to Ultrasonic Sewing – Future Technology

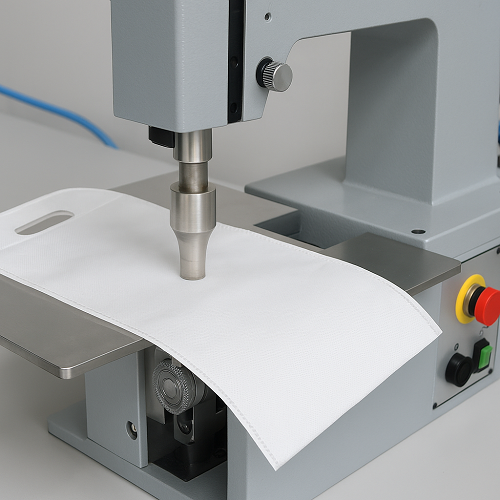

The VietSonic ultrasonic sewing machine utilizes high-frequency waves (approx. 20 kHz) to generate frictional heat, melting and bonding layers of non-woven fabrics, technical textiles, woven PP, and various other soft materials – eliminating the need for traditional needle and thread.

Key Benefits:

- Sharp, strong, and water-resistant welds.

- Completely eliminates lint and excess thread issues – especially critical for medical and cleanroom products.

- Increases production speed up to 4 times compared to conventional sewing, saving labor and cleaning costs.