VietSonic Continuous Ultrasonic Sealing Machine – Modern Welding Solution for Durable Joints

Overview Introduction

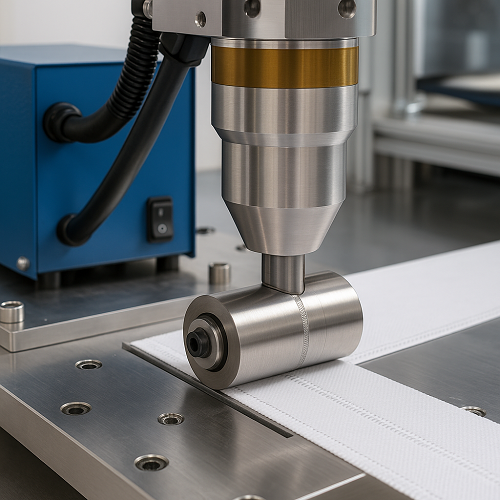

The VietSonic continuous ultrasonic welding machine is a non-thermal welding system that utilizes high-frequency ultrasonic waves (>20 kHz) to bond materials under pressure. This equipment is widely applied for high-tech plastics, non-woven fabrics, and composite products, thanks to its ability to create strong, aesthetic welds without the need for adhesives or bolts.

Outstanding Advantages

- Continuous, High-Speed Welding: Increases productivity, especially in high-volume production lines.

- Strong & Clean Seams: Uniform joint structure, no residue, no rework required. Tensile strength reaches the high levels of the original material.

- No Glue, No Heat Build-up: Protects material quality, reduces consumable costs, and minimizes maintenance labor.

- Eco-Friendly: Produces no smoke or toxic fumes, meeting clean production requirements.