VietSonic Ultrasonic Welding Machine: Efficient Solution for Plastic, LED Electric Boxes & Plastic Parts

In the modern manufacturing industry, ultrasonic welding technology is increasingly asserting its position as a superior solution, especially in the field of welding plastics and complex plastic components. VietSonic‘s ultrasonic welding machines, as detailed below, offer high efficiency, rapid speed, and superior weld quality.

What is an Ultrasonic Welding Machine?

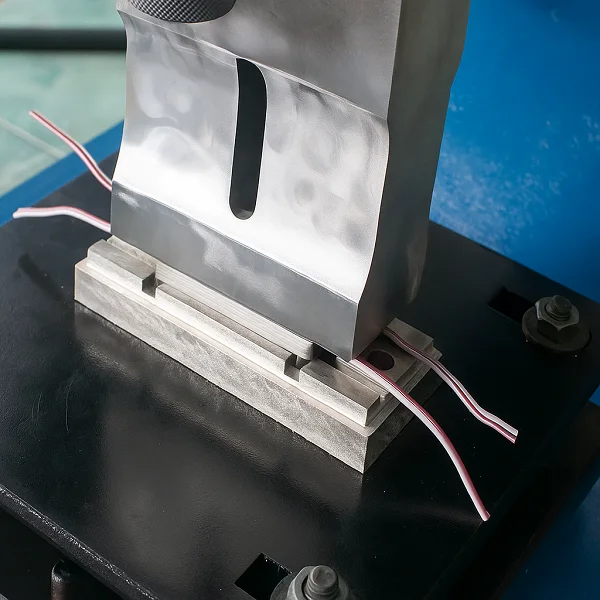

An ultrasonic welding machine uses high-frequency ultrasonic waves to generate frictional heat at the contact point between two material surfaces. This heat melts the material, and then under pressure, the parts bond together to form a solid weld. This process happens extremely quickly, in just a few seconds, ensuring high productivity for production lines.