Ultrasonic Non-Woven Bag Production Line – Optimal Solutions from VietSonic

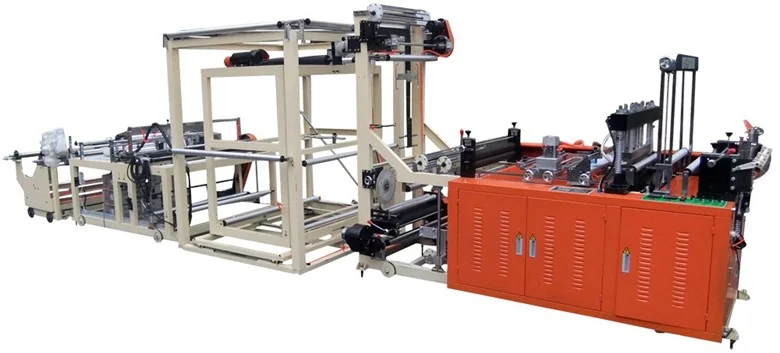

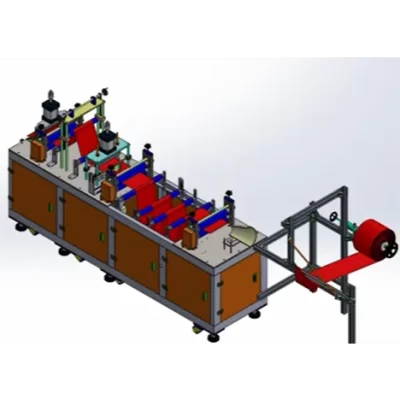

Introduction to the Bag Production Line

As the demand for non-woven fabric bags, box bags, and desiccant bags continues to rise, investing in a modern bag production line has become an inevitable trend.VietSonic – a leading company in Vietnam specializing in ultrasonic technology and manufacturing solutions – provides advanced bag production lines that meet high standards of quality and productivity.