Ultrasonic Sewing Machine for PP Woven Bags – Optimal Solution for Modern Production

Introduction to PP Woven Bags

PP Woven Bags (Polypropylene woven bags) are durable, lightweight, and cost-effective packaging, commonly used for packing grains, fertilizers, chemicals, sugar, salt, and agricultural products due to their high load-bearing capacity, easy reusability, and high safety standards.

Ultrasonic Sewing Technology – Superior Advantages

The VietSonic ultrasonic sewing machine for PP woven bags utilizes high-frequency ultrasonic technology (20–40 kHz) to seal PP film edges without needles, thread, or glue. Thanks to friction generating mild heat, PP fibers melt to form a strong bond while the seam remains aesthetic, clean, and fray-free.

Key Benefits:

- High production speed, reaching up to 60 bags/minute.

- Uniform, sharp sealed edges, good tensile strength, no fiber tearing.

- Clean operation, no smoke or dust, suitable for medical and food standards.

- Labor cost savings, threadless operation, compact and reliable machine.

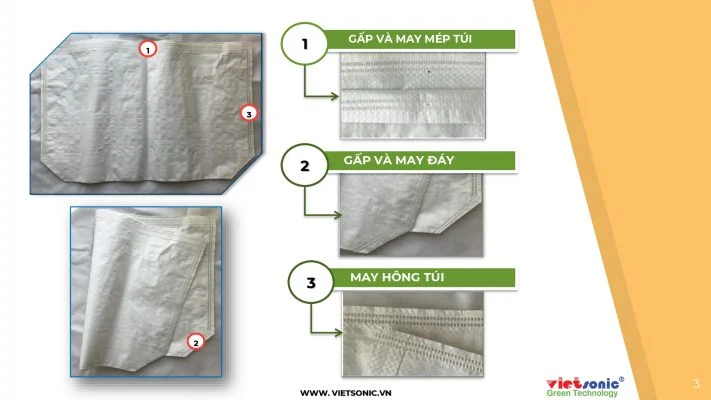

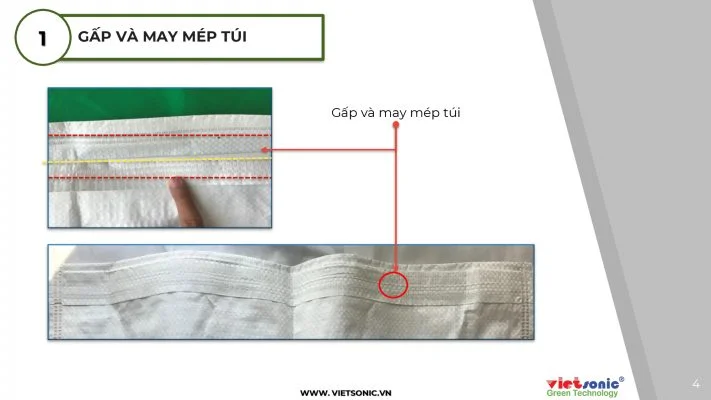

PP Woven Bag Production Process with Ultrasonic Machine

- Prepare PP woven fabric rolls with a density of 40–120 g/m², maximum width up to 1.6 m.

- The ultrasonic machine seals the bag edges without using thread or excessive heat.

- Cutting and sealing can be performed in a single step.

- Create products with customized dimensions (width 100–800 mm, length 200–650 mm) with high precision.

Sample Machine Configuration:

- Ultrasonic Frequency: 20 kHz with 2000 W power.

- Support Heat: 60–120 °C.

- Capacity: Approx. 60 bags/minute.

- Machine Dimensions: ~2.2 × 1.4 × 7 m, Weight ~2000 kg

Technology Comparison: Traditional Sewing, Thermal Glue & Ultrasonic

| Method | Aesthetic Edge | Speed | Cleanliness | Cost |

| Manual / Mechanical Sewing | Often frayed, easy to tear | Low | No | High |

| Thermal Glue / Adhesive Thread | Edges may be uneven | Medium | Glue fumes present | Medium |

| Ultrasonic Machine | ✅ Beautiful, durable | ✅ High | ✅ Very clean | ✅ Low |

Multi-Industry Applications – Suitable for All Scales

Ultrasonic PP woven bag machines are suitable for:

- Industrial packaging: chemicals, fertilizers, cement, plastics.

- Agro-food products: rice, seeds, grains, sugar, salt.

- Advertising bags, gift bags, branded bags requiring logo printing.

- Medium and large-scale production – effective for international orders.

🧠 Why Choose VietSonic?

- Specialized manufacturing in Vietnam, competitive price, fast delivery.

- Consultation & Customization according to needs: size, capacity, bag style.

- After-sales support: 12-month warranty, available spare parts, rapid technical service.

- Free Sample Testing: Send fabric samples, VietSonic will test weld and send back results via video.

- Meets Clean Standards, suitable for use in medical bag or clean food production.

Conclusion

The VietSonic Ultrasonic PP Woven Bag Sewing Machine is a strategic choice for businesses needing efficient, high-quality, and eco-friendly production solutions. From agricultural packaging to commercial bags – everything can be processed quickly, uniformly, and aesthetically without the need for thread or glue.

Need consultation today?

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn