Introduction to VietSonic Ultrasonic Sewing Solutions

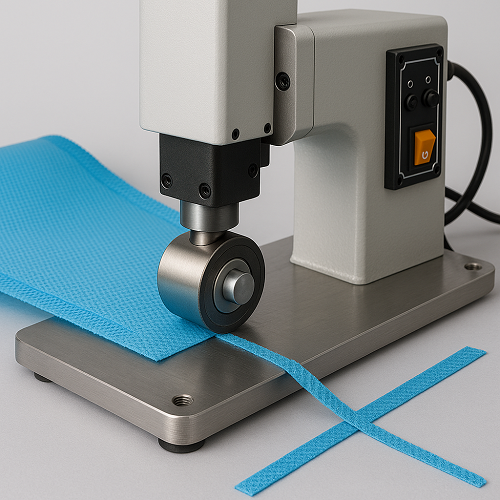

In modern manufacturing trends, businesses constantly face the challenge of speed – quality – savings. Especially in the PP packaging industry, a clean, fray-free, and durable cut is a decisive factor for aesthetics and product value. VietSonic Ultrasonic Sewing Machines utilize 20 kHz frequency ultrasonic waves to cut and seal PP bag edges in a single operation – creating sharp, sealed, and fray-free edges.