VietSonic Ultrasonic Cutter – Smooth Cuts, No Force Needed

Cutting clean without pressure

Are you dealing with problems like:

- Torn edges, burnt corners, or melted material when cutting

- Sticky blades, constant cleaning, time-consuming adjustments

- Mechanical knives wearing out quickly and needing frequent alignment

It’s time to upgrade your cutting technology. With VietSonic‘s ultrasonic cutter, everything becomes smoother:

Less force – no heat – sharp edges – ultra-clean cuts

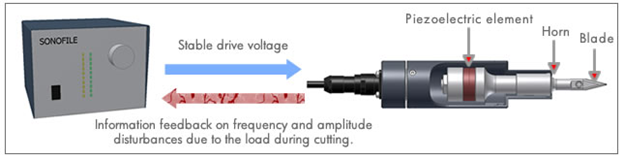

How does it work?

Ultrasonic cutting uses a blade that vibrates at very high frequencies (20–40 kHz). This vibration creates thousands of micro-movements per second, allowing:

- Cutting through materials with almost no applied force

- Minimal friction → no heat buildup

- No dust, no torn or layered edges

- No deformation, even for soft or multi-layer products

In simple terms: the blade just “gently vibrates” and still cuts as clean as a Japanese knife, no pushing needed.

Top benefits everyone agrees on

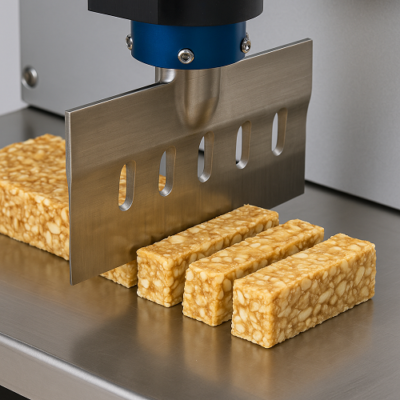

- Clean, sharp edges without post-processing

- No sticking, no burrs

- Fast cutting, easy on both machine and operator

- Super clean – minimal dust – perfect for food factories, composite shops, or garment production

What can it cut?

VietSonic ultrasonic cutter handles a wide variety of materials:

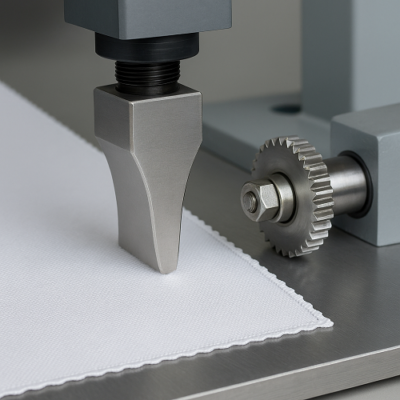

- Technical fabrics, non-woven fabric, synthetic leather, plastic films

- Food: cakes, cheese, sandwiches, candy bars

- Plastics, rubber, foam, composites, multilayer paper

- Biomaterials, packaging, and custom products

Whether it’s soft – hard – brittle – stretchy, it cuts effortlessly.

Who is it for?

- Food startups needing fast, clean, high-quality slicing

- Packaging, printing, or textile workshops looking for speed and accuracy

- Engineers demanding ultra-precise edges with zero sticking

- Lab or R&D teams developing new materials or prototypes

Flexible options to match your needs

- Mini machines: compact, portable, ideal for testing and demos

- Medium-sized benchtop units: great for small-to-medium production

- Industrial systems: fully integrated, continuous cutting on production lines

VietSonic offers customization of blade shape, frequency, power level, and contact materials—tailored to your exact requirements.

Why choose VietSonic ultrasonic cutters?

- Designed and manufactured in Vietnam → easy maintenance and support

- Young, responsive engineering team that understands your needs

- Affordable investment with long-term efficiency

- Highly customizable – unlike rigid, imported machines

- Free test-cutting available when you send your sample

Message us now – test before you buy

No more guessing. Just send us your material, and VietSonic will cut it and send you back real results: images, video, and edge analysis. If it works – let’s go!

Contact em>VietSonic:

- SĐT/Zalo: 0938 49 33 66 (Mr. Hải)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn