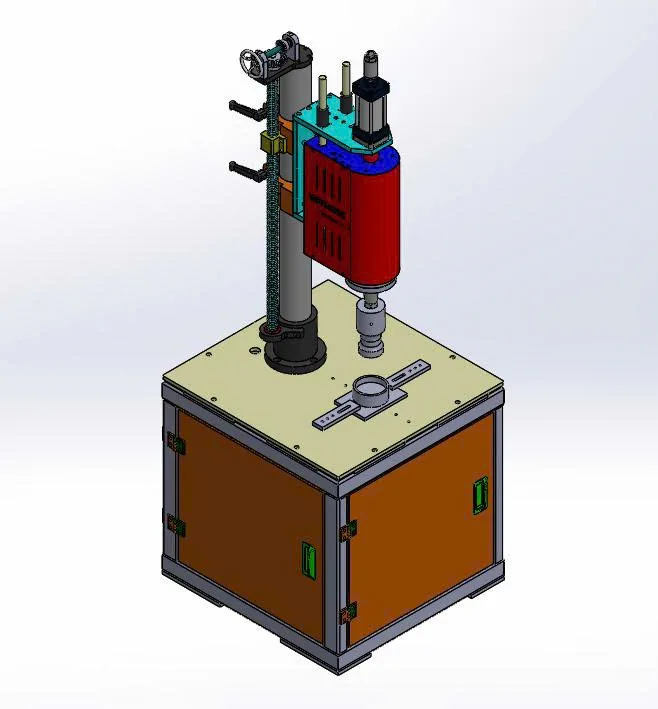

VietSonic Ultrasonic Insulated Cup Welding Machine – Modern Packaging Solution

VietSonic Ultrasonic Insulated Cup Welding Machine – fast, clean, and durable welding technology. A modern packaging solution for the industry.

VietSonic Ultrasonic Insulated Cup Welding Machine – Modern Packaging Solution

1. Introduction to Ultrasonic Insulated Cup Welding Machines

The Ultrasonic Insulated Cup Welding Machine is advanced equipment widely utilized in the packaging industry. This device employs ultrasonic waves to create hermetic seals between layers of insulated cup materials (plastic, composite paper, etc.), ensuring excellent heat retention and food safety.

2. Operating Principle

The machine operates by converting electrical energy into ultrasonic mechanical vibrations (typically 15-40 kHz), generating localized heat via friction between material molecules. Under maintained pressure for a few milliseconds, the materials undergo localized melting and form a robust bond upon cooling.

3. Superior Advantages

- Fast & Efficient: Welding cycle under 1 second, saving time and energy.

- Strong & Aesthetic Welds: No deformation, leaving no visible weld marks.

- Clean & Safe: Adhesive-free, smoke-free, and minimal dust generation.

- Easy Automation: Compatible with modern production lines, ensuring high uniformity rates.

- Long-term Savings: Low failure rate and minimal maintenance costs.

4. Expanded Applications of Ultrasonic Cup Welding Machines

Beyond welding paper or plastic insulated cups, ultrasonic welding machines have a broad range of applications in the food packaging industry:

- Sealing Aluminum Laminated Films: Ensures effective airtight and watertight seals.

- Continuous Welding on Composite Films: Optimizes production processes and enhances product sealing integrity.

- Diverse Material Compatibility: Works with thermoplastics like PE, PS, PVC, ABS — convenient for printed or insulated packaging.

- Precision Component Welding: Capable of welding details such as adapters, pen caps, plastic partitions, and hoods. Applied in various industries including electronics, automotive, and office supplies thanks to precise mold design and high-quality localized technology.

https://www.youtube.com/watch?v=Oek4MpvzuRI

5. Technical Specifications

- Model: VS1532

- Frequency: 15 kHz

- Power Output: 3200 W

- Power Source: 220V – 50/60 Hz

6. Contact Information

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn

- Vietnam Ultrasonic Equipment Co., Ltd. (VietSonic)