Ultrasonic PVC Pipe Welding Machine: Automatic Weld & Cut – Superior Tech for Modern Production

Automatic ultrasonic PVC pipe welding & cutting machine: high speed, cost-saving, strong & aesthetic welds.

Ultrasonic PVC Pipe Welding Machine: Automatic Weld & Cut – Superior Tech for Modern Production

1. Introduction

In PVC pipe manufacturing, precise and clean welding and cutting are paramount requirements. The Automatic Ultrasonic PVC Pipe Welding Machine is a modern solution integrating high-frequency technology, ensuring robust bonds and significant time savings.

2. Operating Principle

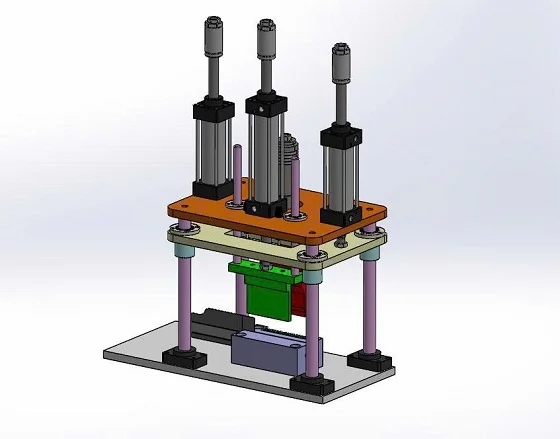

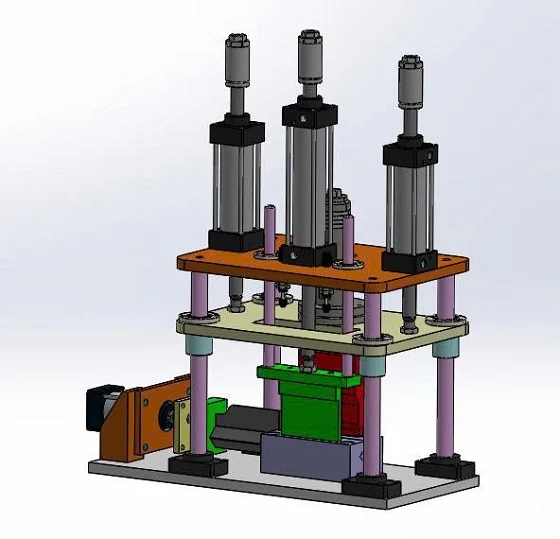

The machine utilizes ultrasonic waves (typically in the 15–35 kHz range), converting electrical energy into mechanical vibrations at the welding horn (sonotrode). Heat is generated via friction between plastic surfaces, causing the PVC material to melt and bond securely. After welding, the pipe is rapidly cooled, creating a sharp, strong, and aesthetic seal.

3. Key Features

- Fully Automated: The machine can weld and cut according to preset programs, ensuring high speed and precision.

- High Welding Speed: Each weld can be completed in just a few seconds.

- Energy Saving: High operating efficiency with significantly lower power consumption compared to traditional methods.

- Quality Welds: High durability, aesthetic finish, requiring no post-weld processing.

- Eco-Friendly: Quiet operation, low noise, and no hazardous emissions.

- Frequency Flexibility: Select models support multiple frequencies (28, 30, 35 kHz) and power outputs from 1,000 W to 8,400 W, suitable for diverse needs.

- Operational Cost Saving: Minimizes labor costs, consumables, and maintenance expenses.

4. Superior Advantages

- High speed and productivity, suitable for large-scale production.

- Strong, aesthetic welds without the need for additional finishing.

- Reduced labor costs and consumable materials.

- Easy integration into automated production lines.

- Effective and environmentally friendly.

5. Technical Specifications

- Model: VS-HCO 2026

- Frequency: 20 kHz

- Power Output: 2600 W

- Power Source: 220 V – 50 Hz

6. Multi-Industry Applications

- Production of pipes for water supply, irrigation, and drainage systems.

- Manufacturing of medical tubing, technical pipes, and engineered plastic components.

- Industries such as automotive, electronics, medical, and packaging, where fast and precise plastic welding is required.

The Automatic Ultrasonic PVC Pipe Welding Machine is the optimal solution for enhancing quality and efficiency in manufacturing. With high speed, sharp welds, and precise cutting, this is a worthy investment technology for modern production lines.

7. Contact Information

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn

- Vietnam Ultrasonic Equipment Co., Ltd. (VietSonic)