VietSonic Ultrasonic Fabric Cut & Seal Machine – Sharp, Fray-Free Edge Solution

Introduction

The Ultrasonic Fabric Cutting & Sealing Machine (Anti-Fray) is an advanced solution from VietSonic Company, designed to process fabric edges quickly, neatly, and without leaving loose threads. This technology is particularly suitable for the garment, accessories, and technical material industries, ensuring high precision and absolute anti-fraying.

Operating Mechanism of Ultrasonic Cut & Seal Machine

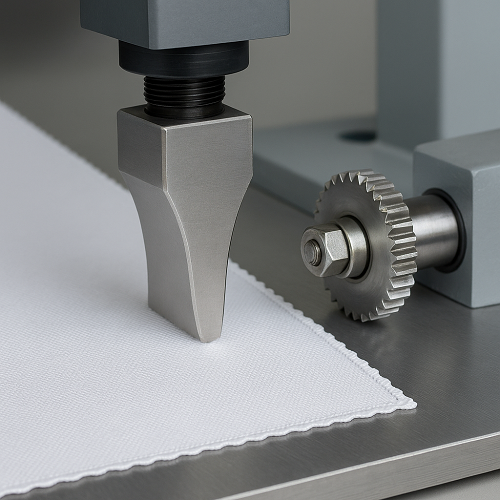

The machine utilizes high-frequency ultrasonic waves (typically 20 – 40 kHz), creating frictional heat right at the cutting point. Under the action of the ultrasonic horn (sonotrode) and the pressure roller, the fabric edge is cut and simultaneously sealed, preventing fraying and tearing.

Machine composition includes:

- Ultrasonic generator with stable power output

- Vibrating welding head (sonotrode)

- Edge forming roller (interchangeable patterns: wave, sawtooth, straight, etc.)