CNC Milling – High-Precision Machining Solutions at VietSonic

1. Introduction to CNC Milling Services at VietSonic

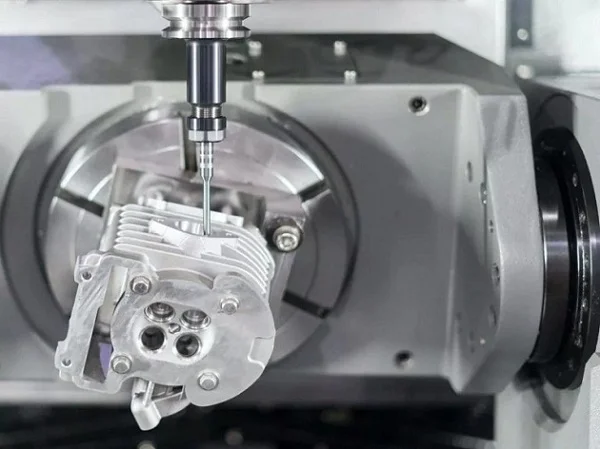

CNC Milling services at VietSonic provide modern, precise, and effective metal machining solutions for businesses in industrial sectors, mechanical manufacturing, mold making, and mass production. With advanced CNC machinery systems and a professional technical team, we ensure compliance with the most stringent technical requirements.

2. Outstanding Advantages of CNC Milling Technology

- High Precision: Extremely low tolerance, suitable for products requiring exquisite detail and exact specifications.

- High Automation: Minimizes human error, significantly increases production efficiency.

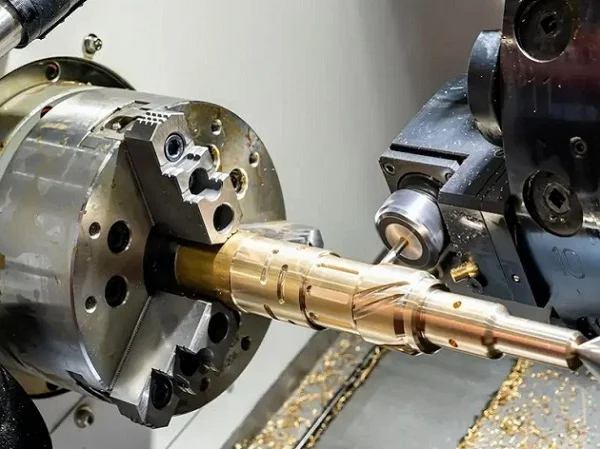

- Diverse Material Machining: From aluminum, stainless steel, copper, and engineering plastics to super-hard alloys.

- Complex Shaping: CNC milling easily creates parts with difficult geometries, slots, holes, inclined surfaces, and 3D contours.

3. Applications of CNC Milling

- Machining machinery details and industrial equipment components.

- Manufacturing electronic components and precision mechanical parts.

- Fabricating molds, dies, and jigs.

- Cutting and shaping high-tech mechanical products.

4. Why Choose VietSonic for CNC Milling Services?

- ✅ Modern CNC Milling Machines: Diverse systems including 3-axis, 4-axis, and 5-axis machines, suitable for all requirements.

- ✅ Guaranteed Quality: Strict inspection processes ensure absolute precision of output products.

- ✅ Reasonable Cost – Fast Progress: Optimizing production time and costs for businesses.

- ✅ Full-Package Service: Consultation on design, programming, machining, and surface finishing.

Contact VietSonic for CNC Milling Services

Are you in need of high-precision mechanical detail machining? VietSonic is the trusted partner for projects ranging from single prototypes to mass production. Contact us for the best advice and quotation.

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn