Rubber Roller Manufacturing – Durable, Precise Solutions from VietSonic

Introduction to Rubber Roller Manufacturing Services

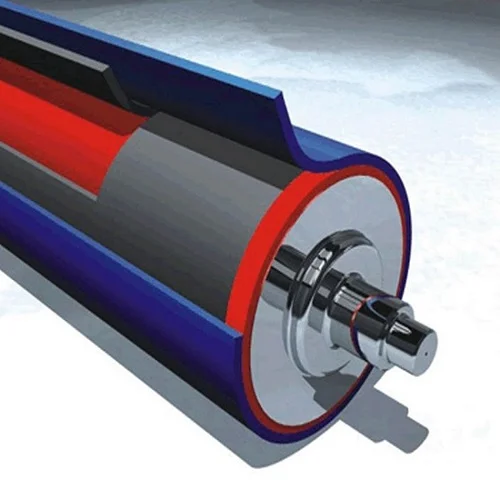

Rubber rollers are critical components in many industries such as printing, packaging, textiles, wood processing, paper production, and food. With characteristics like wear resistance, anti-slip properties, and effective vibration reduction, rubber rollers help machinery operate smoothly and stably.

VietSonic proudly provides high-quality rubber roller manufacturing services, meeting the strict technical requirements of each customer. We use advanced technology and premium rubber materials to ensure durability, precision, and optimal operational capability.

Advantages of VietSonic Manufactured Rubber Rollers

- High Precision: Machined on modern CNC machines, ensuring absolute dimensions and concentricity.

- Superior Material Quality: Heat-resistant, oil-resistant, abrasion-resistant, and chemical-resistant rubber.

- Customized to Requirements: Meeting all size, hardness, and rubber type requirements for specific applications.

- Long Lifespan: Minimizing maintenance and replacement costs.

Applications of Rubber Rollers

- Printing & Packaging Industry: Nip rollers, feed rollers, drive rollers.

- Textile Industry: Fabric tensioning rollers, winding rollers.

- Wood & Paper Industry: Paper press rollers, wood feed rollers.

- Food Industry: Squeeze rollers, dough rolling rollers.

Why Choose VietSonic?

- Years of Experience in manufacturing and machining rubber rollers.

- Modern Machinery System for high-quality products.

- Expert Technical Team, ready to advise on optimal solutions.

- Competitive Pricing, on-time delivery.

VietSonic – Trusted Partner in Rubber Roller Manufacturing

Contact us immediately for consultation and quotation:

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn