Professional AWS Welding Training Course – Skill Enhancement & International Certification

Course Introduction

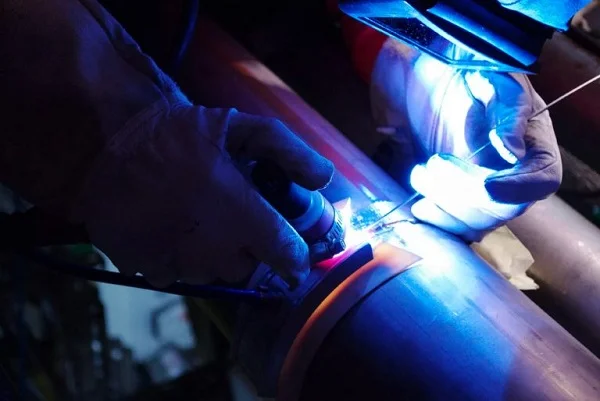

The advanced welding training course based on AWS (American Welding Society) standards is a program designed for welders, technicians, supervisors, and managers in the mechanical engineering and fabrication sectors. The program focuses on three common welding methods: TIG, MIG/MAG, and Laser welding, harmoniously combining theory and practice to help trainees grasp solid knowledge and master practical skills.

The course not only provides professional knowledge of international standards but also guides how to establish and utilize WPS, PQR, WPQ, master robotic welding systems, and practice weld quality inspection according to technical procedures.

Why Participate in This Welding Training Course?

- Master modern TIG, MIG/MAG, and Laser welding techniques.

- Training aligned with international AWS standards – a foundation for CW/CRAW certification exams.

- Learn to read welding blueprints, symbols, and develop WPS procedures.

- Practice directly on real equipment, including robotic welding systems.

- Analyze and handle welding defects; inspect weld quality using VT, PT, UT, RT methods.

- Learn from experienced instructors from top technical universities.

Course Details

1. Training Objectives

- Equip foundational knowledge of TIG, MIG, and Laser welding processes.

- Understand AWS standards regarding materials, joints, welding parameters, safety, and inspection.

- Know how to read welding drawings, symbols, and build WPS/PQR procedures.

- Enhance skills for skilled welders, welding foremen, supervisors, and managers.

2. Training Duration

- Theory: 48 periods

- Practice: 48 periods

3. Instructors

- Assoc. Prof. Dr. Nguyen Thanh Hai – Faculty of Mechanical Engineering, HCMUT – VNU-HCM

- Assoc. Prof. Dr. Nguyen Thanh Truong – Faculty of Mechanical Engineering, HCMUT – VNU-HCM

- MSc. Phan Van Toan – PhD Candidate – Faculty of Mechanical Engineering, HCMUT – VNU-HCM

4. List of Abbreviations

| No. | Abbreviation | Full Name |

| 1 | HCMUT | Ho Chi Minh City University of Technology |

| 2 | VNU | Vietnam National University |

| 3 | TIG | Tungsten Inert Gas |

| 4 | GTAW | Gas Tungsten Arc Welding |

| 5 | MIG | Metal Inert Gas |

| 6 | GMAW | Gas Metal Arc Welding |

| 7 | MAG | Metal Active Gas |

| 8 | LAW | Laser Arc Welding |

| 9 | AWS | American Welding Society |

| 10 | WPS | Welding Procedure Specification |

| 11 | PQR | Procedure Qualification Record |

| 12 | WPQ | Welder Performance Qualification |

| 13 | CWI | Certified Welding Inspector |

| 14 | CW | Certified Welder |

| 15 | CRAW | Certified Robotic Arc Welder |

| 16 | ATF | Accredited Test Facility |

| 17 | PPE | Personal Protective Equipment |

| 18 | QC | Quality Control |

| 19 | VT | Visual Testing |

| 20 | PT | Penetrant Testing |

| 21 | MT | Magnetic Particle Testing |

| 22 | UT | Ultrasonic Testing |

| 23 | RT | Radiographic Testing |

5. Theory Training Curriculum

| No. | Content | Duration (periods) |

| Module 1 | Evaluation process and welder certification according to AWS standards

1. Overview of AWS Welder Certification

1.1 Distinguish between:

1.2 Validity period – scope – renewal

2. Components of AWS certification dossier

3. Official certification exam process (AWS CW – issued by ATF)

4. Internal certification process (confirmed by company & CWI)

5. Requalification

6. Comparison of internal vs. international certificates

7. Responsibilities of parties in certification

|

4 |

| Module 2 | GTAW (TIG) Welding

1. Overview and working principle

2. Structure and TIG welding equipment

3. Welding modes and operating parameters

4. Consumables: base metal and filler metal

5. Practical applications of TIG welding

6. Common defects and remedies

7. Safety in TIG welding

|

4 |

| Module 3 | GMAW (MIG/MAG) Welding

1. Overview and working principle

2. Structure and MIG/MAG welding equipment

3. Welding modes and operating parameters

4. Consumables: base metal and wire

5. Practical applications of MIG/MAG welding

6. Common defects and remedies

7. Safety in MIG/MAG welding

|

4 |

| Module 4 | Overview of LAW (Laser Welding)

1. Overview and working principle

2. Structure and LAW equipment

3. Welding modes and operating parameters

4. Consumables: base metal and filler

5. Practical applications of LAW

6. Common defects and remedies

7. Safety in LAW

|

3 |

| Module 5 | AWS Standard Structure and Related Documents

1. AWS D1.1 (steel), D1.2 (aluminum), QC7, B2.1, A2.4

2. ASTM vs. AWS vs. ISO – Understanding correlations

3. How to read and apply standards in business

|

2 |

| Module 6 | Welding Technical Documentation – WPS, PQR, WPQ

1. Explaining the role and creation process

2. Reading and analyzing a real-world WPS case

3. Application in quality management and certification exams

|

2 |

| Module 7 | Base Materials & Consumables

1. Carbon steel, stainless steel, aluminum, and alloys

2. Properties affecting weldability

3. Classification of electrodes/wires according to AWS A5.x

4. Shielding gases – by material and welding method

|

3 |

| Mid-term Examination | 4 | |

| Module 8 | Influence of Material Surface

1. Oxide layers, grease, rust – cleaning methods

2. Material thickness and current selection

3. Importance of weld edge preparation

|

2 |

| Module 9 | Welding Symbols and Blueprints (AWS A2.4/ISO 2553)

1. Weld symbols, welding positions, joint types

2. Reference lines, arrows, supplementary notes

3. Distinguishing technical drawings vs. welding drawings

|

2 |

| Module 10 | Defects and Weld Inspection

1. Types of defects: undercut, lack of fusion, cracks, etc.

2. Causes – consequences – remedies

3. Inspection methods (VT, PT, MT, UT, RT) – pros and cons

|

4 |

| Module 11 | Welding Safety and Organizational Role

1. PPE, toxic gases, arc radiation

2. Responsibilities of welders, team leaders, supervisors, and managers

3. Process monitoring – logging – record keeping

|

2 |

| Module 12 | Robotic MIG/MAG Welding: Principles and Characteristics

1. Robotic system structure: manipulator, controller, wire feeder

2. Characteristics of MIG/MAG arc in automated welding

3. Differences between manual and robotic welding: travel path, speed, torch angle

4. Effect of torch position and robot speed on weld quality

5. Common robot welding defects: off-seam, spatter, poor penetration

6. WPS setup standards for robotic welding per AWS

|

4 |

| Module 13 | AWS Standards and Certification in Robotic Welding

1. Roles related to robotic welding per AWS

2. Distinguishing between Certified Welder (CW) and Robot Operator/Programmer

3. Applicable AWS standards: D16.4, QC19, B5.25

4. Path to AWS Certified Robotic Arc Welding (CRAW)

5. Requirements for programming skills, WPS, weld inspection

6. Simulation of CRAW exam according to AWS D16.4

|

4 |

| Module 14 | Theory Examination (40 multiple choice + 2 essay questions)

(Certificate of completion for internal AWS welding theory program)

|

4 |

6. Practical Training Curriculum

| No. | Content | Duration (periods) |

| Session 1 | Equipment Preparation and Pre-weld Safety

Installation and inspection guide:

|

4 |

| Session 2 | Adjusting Welding Modes per Actual WPS

Reading and operating sample WPS

|

4 |

| Session 3 | Troubleshooting Practice

Identifying common situations:

|

4 |

| Session 4 | Recording Parameters and Welding Records

Guide to creating:

|

4 |

| Session 5 | Post-weld Inspection (Visual and Gauges)

Visual inspection practice per AWS D1.1

|

4 |

| Session 6 | Rework Practice

Rewelding defective parts according to instructions

|

4 |

| Session 7 | Mock Test for AWS CW Certification

Simulating the exam process:

|

4 |

| Session 8 | Comparing Pass/Fail Welds – Learning from Mistakes

Viewing actual samples or photos

|

4 |

| Session 9 | Material Identification Practice – Reading Steel/Aluminum Symbols

Using AWS A5.x and ASTM classification tables

|

4 |

| Session 10 | Practice Welding Positions 1G – 4G per AWS D1.1

Practicing each position with steel, aluminum, stainless samples:

|

4 |

| Session 11 | Robotic MIG/MAG Welding Practice

|

4 |

| Final Examination & Evaluation | 4 | |