VietSonic Ultrasonic Homogenizer – An Effective Solution for All Industrial Homogenization Processes

Introduction

In various industries such as food, cosmetics, pharmaceuticals, and nanomaterials, homogenizing ingredients to create a smooth, stable, and long-lasting mixture is an essential step. Compared to traditional mechanical methods, ultrasonic technology stands out for its ability to provide fast homogenization, high efficiency, and low temperatures, preserving the physical and chemical properties of the material.

VietSonic proudly offers high-quality ultrasonic homogenizer machines, independently designed and manufactured in Vietnam. Our systems are fully customized to meet specific requirements, with technical support from lab-scale development to full-scale production.

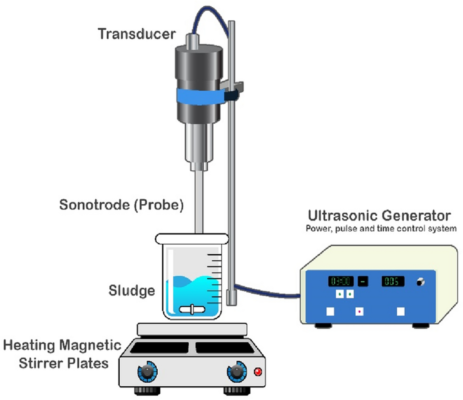

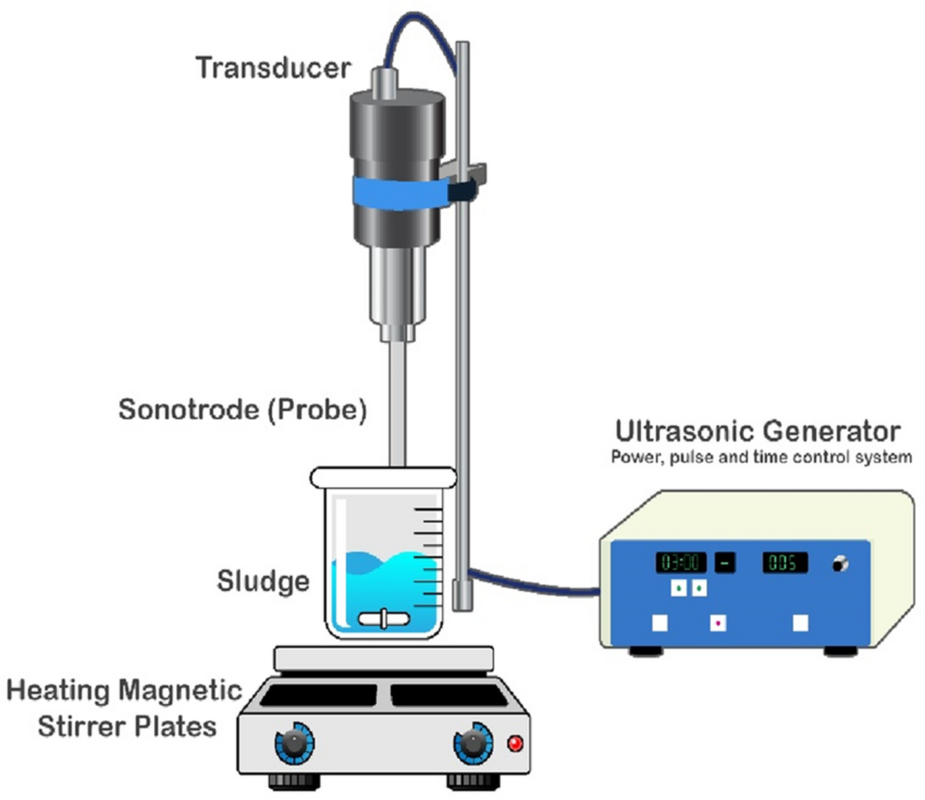

Working Principle

The VietSonic ultrasonic homogenizer operates based on the cavitation phenomenon—microscopic vacuum bubbles form and collapse in the liquid due to high-frequency ultrasonic waves. This process generates extremely strong shear forces capable of breaking up oil droplets, solid particles, or biological cells. As a result, the material is processed into a homogeneous and stable state without the need for high temperatures or chemical additives.

This is particularly important in applications that require low temperatures, such as enzyme extraction, vitamins, or biologically active ingredients that are sensitive to heat.

Advantages of VietSonic Ultrasonic Homogenizers

- Fast homogenization in just seconds

- Maintains low sample temperatures

- Capable of dispersing particles down to <100 nm

- No chemical emulsifiers required

- Preserves biological activity; ideal for heat-sensitive products

- Easy-to-operate design, simple maintenance

- Affordable investment, local technical support

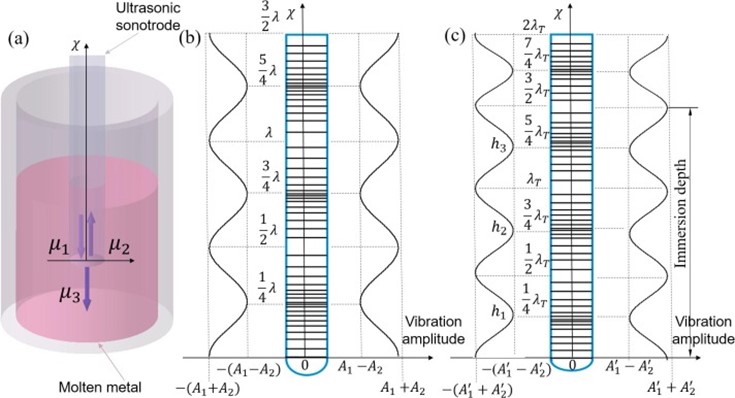

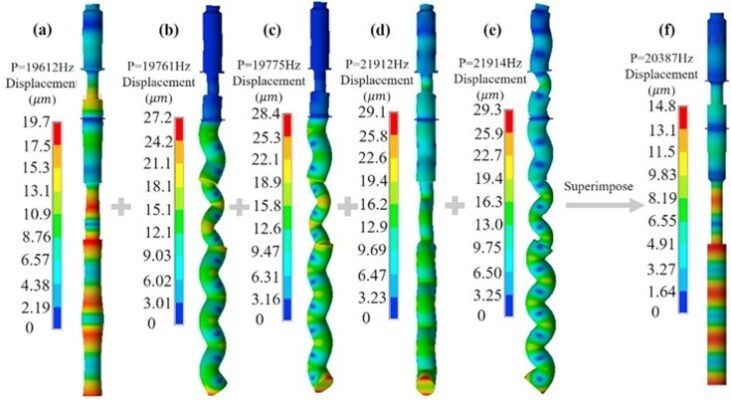

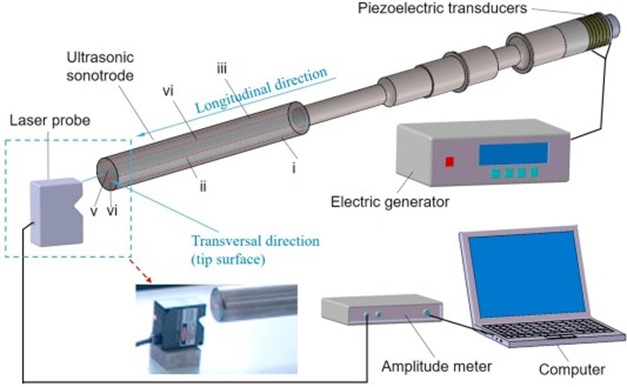

Independent Design and Finite Element Simulation of Sonotrode

A key strength of VietSonic lies in our ability to independently design the entire system—from the housing and power module to the sonotrode (ultrasonic horn). We apply finite element simulation of sonotrode (FEM) technology to:

- Precisely tune resonance frequency and vibration amplitude

- Maximize energy transfer into the sample

- Minimize heat loss and unwanted external vibration

- Extend sonotrode lifespan under continuous operation

This comprehensive design process enables VietSonic to deliver high-performance machines tailored to each customer’s specific application.

Customization for Different Liquid Types

Not all liquids are the same—some are viscous, volatile, contain suspended solids, or are heat-sensitive. VietSonic ultrasonic homogenizers allow fine-tuning of power, amplitude, and sonotrode structure to ensure compatibility with different liquid types, including:

- Fruit juices: preserving natural color, flavor, and enzymes

- Cosmetic serums: forming stable emulsions without synthetic emulsifiers

- Pharmaceutical suspensions: evenly dispersing active ingredients

- Nanomaterial suspensions: achieving uniform dispersion, anti-agglomeration, and nanoscale particle size

This adaptability to fluid properties ensures improved efficiency, consistency, and batch-to-batch reliability.

Real-World Applications by Industry

Food & Beverage Industry

- • Homogenizing plant-based milk, sauces, fruit juices

- • Improves consistency, extends shelf life

- • Non-thermal processing preserves nutrients

Pharmaceutical & Biotech Industry

- Enzyme, RNA, and protein extraction via ultrasonics

- Homogenizing active ingredients in suspensions

- Replaces expensive enzymatic breakdown methods

Cosmetic Industry

- Emulsification of creams, gels, lotions, serums

- Achieves smooth textures, prevents phase separation

- Reduces need for synthetic surfactants

Nanomaterials Industry

- Dispersing TiO₂, ZnO, silica, graphene nanoparticles

- Enhances stability and functional performance

- Suitable for printing, nano coatings, batteries, electronics

VietSonic Ultrasonic Homogenizer Models

- Laboratory models: 100–500 W, for 5–1000 mL sample volumes

- Pilot/Small-scale production: 1000–2000 W, for 1–20 L batches

- Industrial systems: 3000–5000 W+, for >50 L processing, integratable into automated production lines

All systems are designed and assembled in Vietnam, fully customizable per client specifications.

Why Choose VietSonic

- Independently designed and manufactured in Vietnam

- Modern finite element sonotrode simulation for maximum performance

- Optimized for fast homogenization with low temperature rise

- Fully customizable for different liquid types and applications

- In-country technical support, maintenance, and spare parts

- Cost-effective, durable, and user-friendly systems

Contact Us for Consultation and Orders

If you’re looking for a fast, efficient, and affordable homogenization solution that’s tailored to your unique product, contact VietSonic today for consultation and quotation.

- Phone: 0938.493.366 – Mr Hải

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn

VietSonic is committed to accompanying you through every stage—from design and testing to installation and long-term operation.