Ultrasonic Sewing Machine for Drawstring Non-Woven Bags – Modern Solution from VietSonic

Product Introduction

The ultrasonic sewing machine manufactured by VietSonic is a specialized device for creating drawstring non-woven fabric bags – a product line increasingly chosen by businesses to replace plastic bags. Applying modern ultrasonic welding technology, the machine uses no needles or thread but utilizes ultrasonic waves to bond fabric quickly, securely, aesthetically, and in an environmentally friendly manner.

Configuration of VietSonic Non-Woven Bag Sewing Machine

| Technical Parameter | Details |

| Operating Frequency | 20kHz |

| Power Output | 1500W – 2000W depending on model |

| Working Speed | 0 – 20 m/min (adjustable) |

| Power Supply | 220V / 50Hz |

| Sealing Width | 5mm – 12mm depending on the roller mold |

| Machine Weight | Approx. 70 – 100kg depending on version |

| Suitable Materials | Non-woven fabric (PP non-woven), other thin fabrics |

| Working Table | Height adjustable, convenient operation |

| Upgrade Options | Logo printing unit, foot pedal, automatic speed control |

Production Process of Drawstring Non-Woven Bags with Ultrasonic Machine

- Material Preparation

- Select non-woven fabric with required size and color.

- Cut fabric to standard dimensions (according to desired bag length).

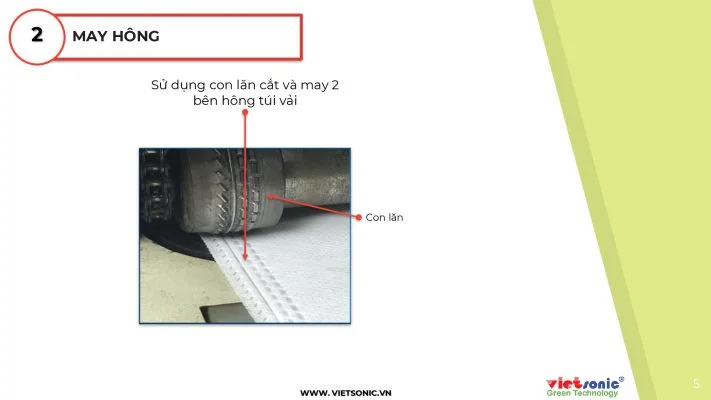

- Sewing Bag Edges and Bottom with Ultrasonic Machine

- Feed the fabric sheet into the machine; the machine uses ultrasonic waves to seal the bag edges and bottom.

- Seams are strong, requiring no sewing thread or glue.

- Creating Drawstring Channel

- Use the ultrasonic machine with a round mold set to create the drawstring channel.

- Cut holes or leave small gaps for threading the drawstring later.

- Threading Drawstring

- Thread the string through the welded bag mouth, using support machines for mass production.

- Cotton string, nylon string, or small rolled non-woven fabric can be used.

- Printing and Finishing

- Use screen printing, heat transfer printing, or direct logo stamping technology.

- Quality check, packaging, and delivery.

Benefits of Using VietSonic Drawstring Bag Machine

- Save Production Costs: No thread cost, shortened production time.

- Enhance Brand Value: Print logos directly on bags for packaging and gifts.

- Increase Productivity: Mass production with stable quality, less dependent on manual skills.

- Safe & Eco-Friendly: No smoke or dust generation, no chemical usage.

🌱 Practical Applications

- Drawstring bags for event gifts

- Bags for cosmetics, fashion, medical products

- Fabric bags for retail and supermarkets

- Student uniform bags, shoe bags, clothing bags

✅ VietSonic – Leading Ultrasonic Machine Partner

With over 10 years in the ultrasonic technology field, VietSonic commits to bringing:

- High-quality products, precision machining.

- Warranty, full operation manuals, on-site technical support.

- Competitive prices, fast dispatch, nationwide delivery.

📞 Contact Information

VIETNAM ULTRASONIC EQUIPMENT COMPANY LIMITED (VietSonic)

- Hotline: 0938 49 33 66 (Mr. Hai)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn