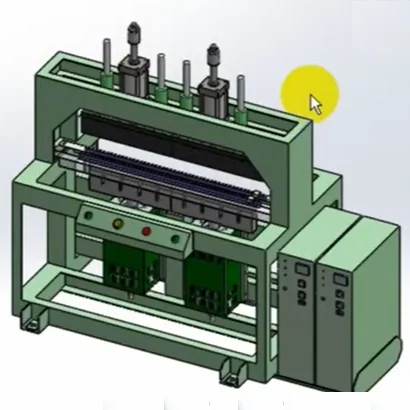

Ultrasonic Welding Machine for PVC Bathtub Lids – High-Tech Solution

1. Overview Introduction

The ultrasonic welding machine for PVC bathtub lids is a breakthrough solution in the plastics industry: heat-free, no additives required, ensuring **durable, aesthetic welds** and **no toxic smoke generation.**

2. Outstanding Advantages of Ultrasonic Technology

- Cold welding via frictional heat: Utilizes 15 kHz ultrasonic waves, power up to 4,200 W (2 ultrasonic heads), creating welds up to 900 mm.

- Fast speed – Neat weld lines: No need to melt the entire part, especially suitable for large products like bathtub lids.

- High precision, low defect rate: Pressure and frequency are automatically controlled, minimizing deformation, ensuring industrial standards.

- Cost and energy savings: No heating elements used; localized equipment helps reduce reliance on imports.

- Safe and eco-friendly: No smoke, no emissions; suitable for modern manufacturing environments.