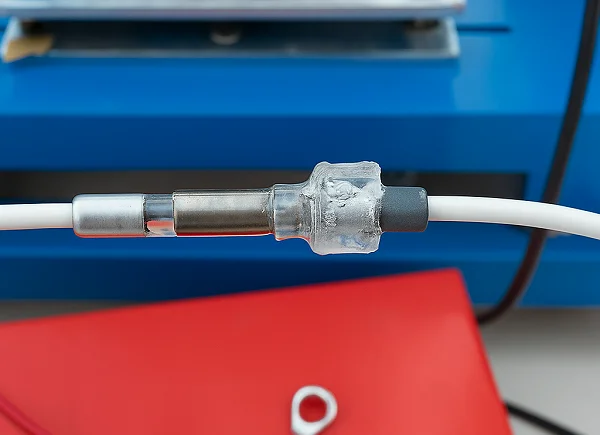

Application of Ultrasonic Plastic Welding Machines in Protecting Automotive Wire Connections with Precision and Durability

1. Introduction

Ultrasonic plastic welding machines use high-frequency sound waves (20–40 kHz) to generate frictional heat between plastic materials, enabling fast and secure bonding of automotive wire joints — without the need for adhesives or solvents.

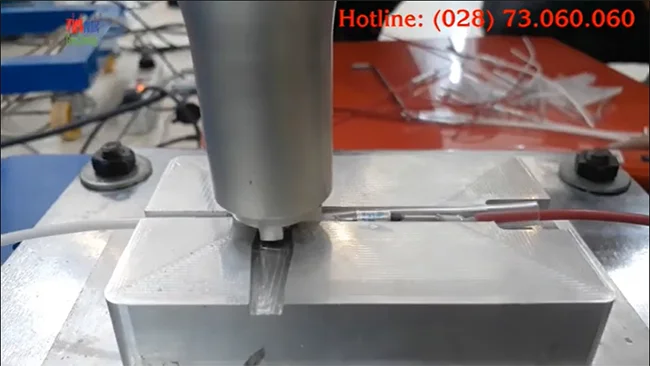

2. Working Principle

- Ultrasonic waves are transmitted to the welding horn (sonotrode), creating mechanical vibration at the joint area.

- The applied pressure and vibration generate frictional heat, melting the plastic material.

- Once the temperature reaches the melting point, the plastic diffuses and bonds tightly before rapidly cooling.

- The entire process takes only 0.1 to 1 second, ensuring high speed and precision.