Effective Ultrasonic Welding Solutions for Thin Films & Plastic Strips with VietSonic Multi-function Machines

1. Introduction to Thin Film Ultrasonic Welding Technology at VietSonic

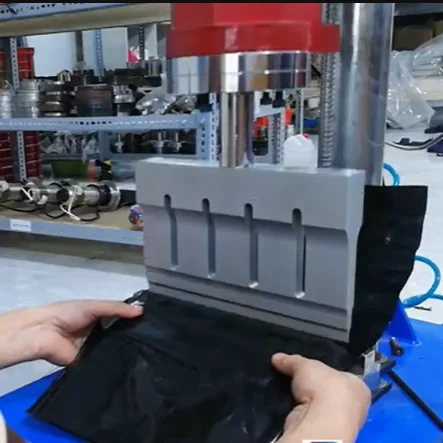

Ultrasonic welding technology for thin films and plastic strips at VietSonic is the optimal solution for thin materials and engineering plastics. With a power output of up to 2,000 W and a frequency of 20 kHz, the device allows for the creation of sharp, strong weld lines without the use of glue or adhesive tapes – helping to reduce costs and production time more effectively.

2. Outstanding Advantages of VietSonic Multi-function Welding Machine

- High Frequency, Large Capacity: 20 kHz combined with 2 kW power is suitable for a variety of materials such as PP, PE, ABS, PVC…

- Strong, Airtight/Watertight Strip Welds when using specialized rollers.

- Horn (Sonotrode) Design: Knurled/toothed design with expanded width helps increase productivity and precision.

- Multi-functional Device capable of welding thin films, plastic strips, spot welding, cap reinforcement, non-woven fabrics, laminated films, etc., for multi-industry applications.