VietSonic Ultrasonic Soldering System – A Flux-Free, High-Reliability Bonding Solution

Introduction to the Technology

In the era of clean and precision manufacturing, industries such as electronics, biomedical, optics, and renewable energy face the challenge of bonding “difficult” materials like aluminum, stainless steel, glass, ceramics, and composites.

The ultrasonic soldering technology developed by VietSonic offers a complete solution — enabling strong, clean, flux-free joints with high durability and reliability.

Working Principle

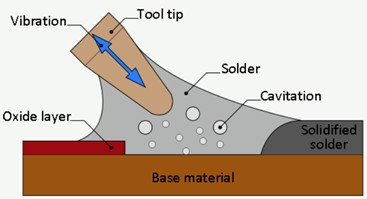

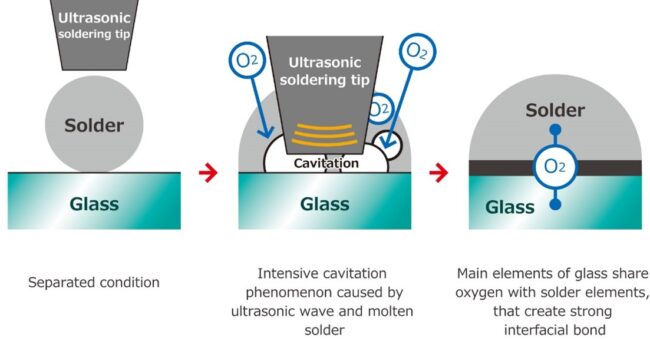

The system operates based on the synergy of:

- Solder heating: Melting the solder alloy at ~300–450°C.

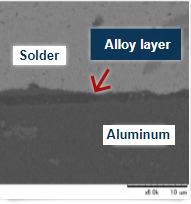

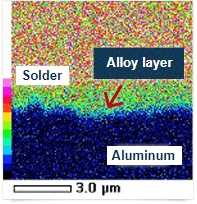

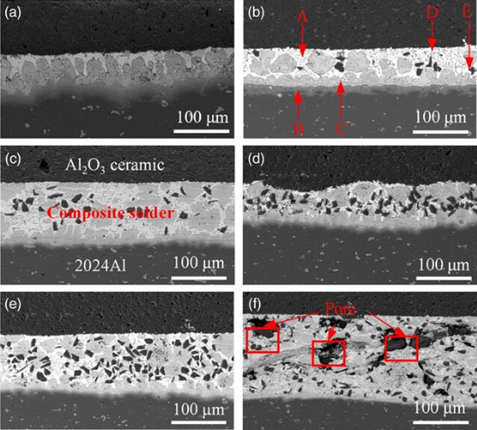

- Ultrasonic waves at 20–60 kHz: Inducing cavitation to disrupt oxide layers and clean surfaces.

- Active solders: Containing Ti, Zr, In… for excellent adhesion on challenging substrates.

Key Advantages

- No flux required: Eliminates corrosion risk and post-cleaning steps.

- Bonds difficult materials: Aluminum, titanium, ceramics, glass, sapphire, etc.

- Strong and reliable joints: Excellent wetting and high mechanical integrity.

- Cleanroom compatible: No smoke, no chemical emissions — safe for ISO clean environments.

Comparison with Traditional Methods

| Criteria | With Flux Soldering | Induction Soldering | VietSonic Ultrasonic Soldering |

| Requires flux chemicals | Yes | No | No |

| Works on special materials | Low | Medium | Very high |

| Bond strength | Medium | High | Very high |

| Smoke / toxic byproducts | Yes | No | No |

| Cleaning after soldering | Yes | No | No |

Structure & Customizability

VietSonic custom-designs each module for flexibility and application fit:

- Ultrasonic generator: Precisely controls frequency and amplitude.

- Integrated soldering tip: Combines heating + FEM-optimized sonotrode.

- Robot-mountable frame: Compatible with pick-and-place or CNC platforms.

- Touchscreen control: Easy operation, logging, and real-time adjustment.

Real-World Applications

- Precision electronics: Fine-pitch PCBs, sensitive components, non-flux conditions.

- Biomedical & optics: Bonding ceramics/glass with microscale circuits.

- Renewable energy: Solar panels, sensors, oxide-coated terminals.

- Optoelectronics: Sapphire bonding, transparent substrates, thin coatings.

Automation-Ready Integration

Compatible with automated lines:

- SCARA robots, 6-axis arms, CNC worktables.

- Communication: Modbus, Ethernet, RS485.

- Vision-assisted positioning and geometry-based programming.

Certifications & Testing

- Validated on over 10 materials: Al, SS, glass, ceramics, composites…

- Proven by pull tests, shear tests, oxide-layer adhesion.

- Certified for cleanroom ISO Class 6 compatibility.

Support, Warranty & Service

- Application consultation: Sample evaluation and live demo support.

- 12-month warranty, fast replacement parts available in Vietnam.

- On-site training, detailed manuals, and video tutorials.

Contact for Consultation & Orders

- Website: https://vietsonic.vn

- Phone / Zalo: 0938.493.366 – Mr. Hải

- Email: info.vietsonic@gmail.com

VietSonic is committed to supporting you from sample testing and tailored customization to stable installation and long-term operation. Let us be your trusted partner in clean, durable, chemical-free soldering technology.