Ultrasonic Extraction Redefined – Maximize Efficiency, Preserve Nature

Time to Extract Smarter

Looking to extract essential compounds from natural materials without losing aroma, color, or bioactivity?

Need a device that’s not just powerful – but precise, stable, and adaptable to your specific product?

VietSonic’s ultrasonic extraction system is built for exactly that. No long soaking. No heat damage. No quality loss. Just high performance, fast processing, and clear results.

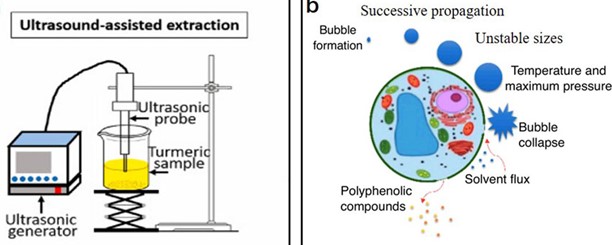

Cavitation Technology – Power from Micro-Motion

When ultrasonic waves pass through a liquid medium, they create millions of microscopic bubbles. As these bubbles collapse, they generate instant bursts of heat and pressure, along with intense shear forces.

These forces are strong enough to break plant cell walls, releasing the valuable compounds inside – quickly and cleanly. And because the process runs at low temperatures, all the flavor, fragrance, and bioactive integrity is preserved.

Not Just Powerful – Intelligently Engineered

At VietSonic, we don’t simply assemble machines – we design every part from the ground up. Especially the sonotrode – the core energy transmitter – which is digitally modeled using Finite Element Method (FEM) simulation to:

- Optimize resonance frequency for each application

- Maximize energy transfer into the liquid

- Minimize unwanted heat and vibration

- Ensure mechanical durability in continuous use

This precision engineering delivers a system that performs consistently, scales effortlessly, and adapts to your real-world process.

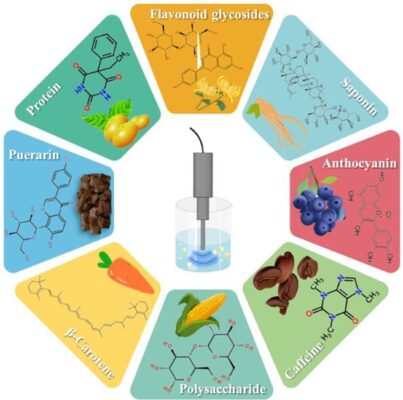

Whatever You Process – We’ve Got You Covered

Food & Beverage

- Extract essential oils from citrus peels and herbs

- Recover antioxidants from tea, grapes, vegetables

- Maintain natural flavors and nutrients, no thermal degradation

Cosmetics & Personal Care

- Isolate bioactive extracts from turmeric, rose, aloe

- Ideal for organic beauty products

- Used in natural serums, lotions, gels

Pharmaceuticals & Herbal Remedies

- Extract alkaloids, flavonoids, saponins from roots, leaves, seeds

- Boost extraction yield and reduce processing time

- Perfect for supplements and functional ingredients

Biomaterials & Nanotech

- Extract cellulose, pectin, or biosilica from agro-waste

- Support nanoparticle dispersion and multi-phase mixing

Flexible Configurations for Any Stage of Production

- Lab-scale systems: 100–500 W, 50–1000 mL – for R&D

- Pilot-scale systems: 1000–2000 W, 1–20 L per batch

- Industrial systems: 3000+ W, 50 L and above – customizable for continuous or batch processing, with cooling, filtering, and circulation options

All models are fully customizable, from sonotrode design to contact materials and operational modes – your needs define the system.

Why So Many Professionals Choose VietSonic?

- In-house design and manufacturing in Vietnam

- FEM-driven sonotrode optimization for peak performance

- Proven efficiency across hundreds of sample types

- Easy integration with your existing workflow

- Dedicated technical support and rapid response

- Competitive investment, long-term reliability

Looking for More Than Just a Machine?

Let VietSonic partner with you through every stage – from concept and testing to real-world implementation.

Contact us today to get started:

- Phone: 0938 49 33 66 (Mr. Hải)

- Email: info.vietsonic@gmail.com

- Website: https://vietsonic.vn

From lab to factory – VietSonic is your trusted partner in modern, high-performance ultrasonic extraction.